This is a simple fix that most anyone can do without much knowledge of airsoft guns. For this example I'm going to use an APS M4 but it will work the same on any single piece hopup unit and can be applied to other guns beyond M4's. Really it depends on how the hopup is pushed against the gearbox, if it uses a spring like most do then it should be possible to do this technique.

Base gun

Things you need: Really all you need to do this mod is a couple small oring's that will fit snugly over the inner barrel that aren't so big that they stop the assembly from going together. As well you might need some minor tools to get to the hopup on your particular gun, since this is a general guide I'm going to assume you know how to tear apart your own gun to the point you can access the hopup chamber and inner barrel.

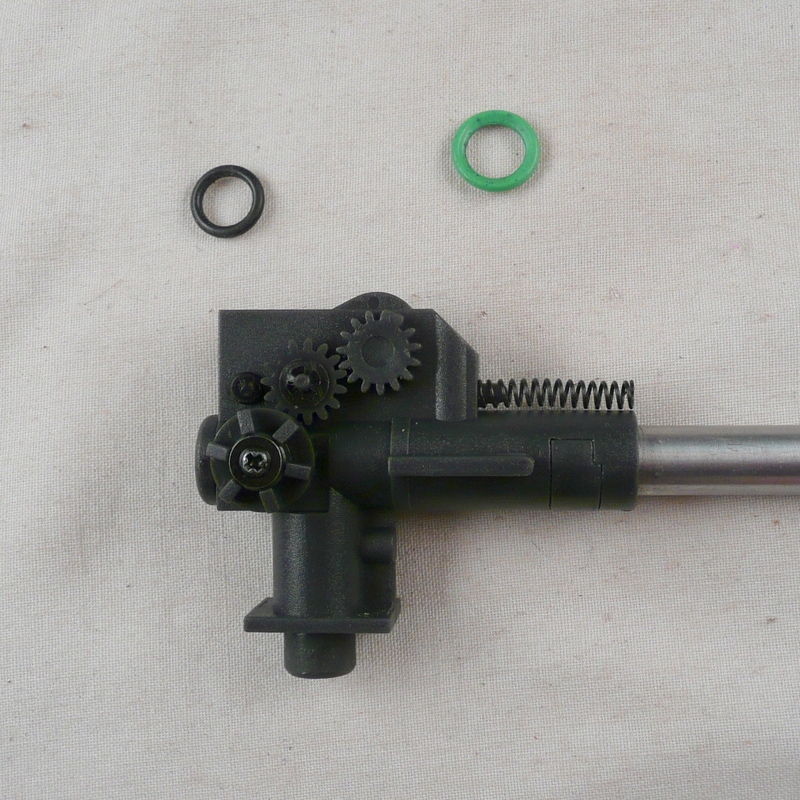

Oring's and Hopup/inner barrel

Problem: On certain magazines the feed tube is further forward or backward which causes the hopup to move forward which creates an air leak between the nozzle and hopup bucking. The stock solution to this is a small spring about the size of a bic pen spring to push the hopup against the gearbox. The problem is the magazine is long and has allot of leverage which means sometimes moving the magazine will cause serious drops in FPS and consistency.

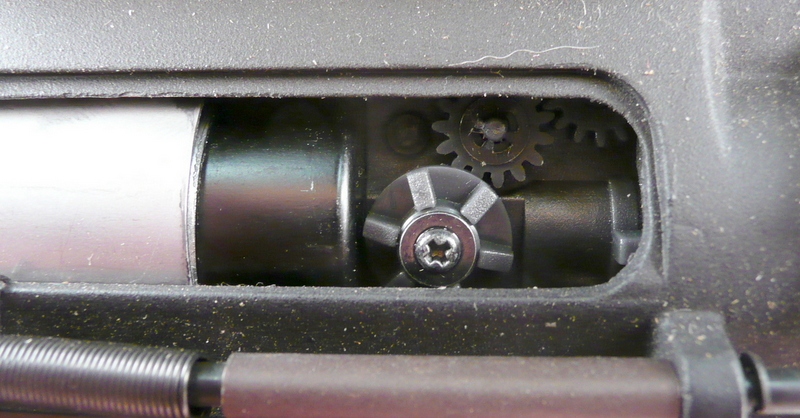

Hopup Unit pressed firmly against gearbox

Solution: So someone out there(not me) thought about using an oring as a shim more less to push the inner barrel against the outer barrel thereby pushing the hopup chamber back against the gearbox with more force. This gives you more consistent pressure, eliminates that movement or most of it that can cause a problem. I've seen this problem to varying degree's on allot of guns, recently I saw an SR25 that was a 500fps gun consistently shooting 400 or so FPS. Took a quick look and noticed it was just using a spring, added a couple orings and back to 500fps consistently. So this can be a huge compression leak that is fairly hard to find but simple to solve. I forgot to mention when typing this. This particular gun uses two orings to get the right amount of pressure. Other guns might need more or less, the key is getting gentle pressure holding the hopup chamber against the gearbox as mentioned. But two orings may be just right or not depending on the gun. I've got several that use more or less based on how sloppy the QC is, as well as brand and model. So don't just toss two one because I said so;) Make sure when assembling the upper on the lower that it's putting a snug pressure and looks like the picture of the pin hole below with a little overlap but not much.

Here you can see the step that the oring will apply pressure against. Hopup unit with orings put on the outer barrel, you can remove the spring or leave it doesn't matter.

Hopup unit with orings put on the outer barrel, you can remove the spring or leave it doesn't matter. Hopup unit back installed in the upper.

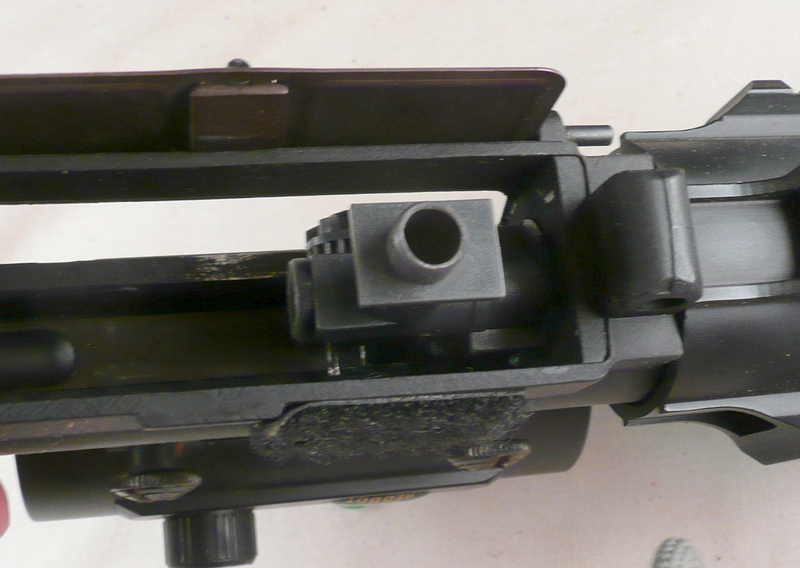

Hopup unit back installed in the upper. Upper and lower back together, note there is a little step of distance the upper will have to go further back onto the lower to insert the pin. That's about right in my opinion, just enough give it doesn't take allot of force to put them together maybe 5-10lbs max.

Upper and lower back together, note there is a little step of distance the upper will have to go further back onto the lower to insert the pin. That's about right in my opinion, just enough give it doesn't take allot of force to put them together maybe 5-10lbs max.

Downsides: Really I don't see any downside to this, when shimming the hopup to the gearbox you don't want too much pressure. You want it snug, so when you slide the upper back in place you need to apply a little pressure to the upper to install the front assembly pin. The upside of this mod as well is the extra pressure on the front pin will make sure it's not going to fall out on it's own if your gun is a little sloppy.

I'm sure there are plenty of guys out there familiar with this technique, and are using it. But there might be some guys out there that haven't seen it or don't use it. In my experience there is little reason not to do this, and it can solve allot of consistency problems when it comes to the hopup/nozzle airseal.

Take care!

Luke

EDIT: Added information about how many orings to use.